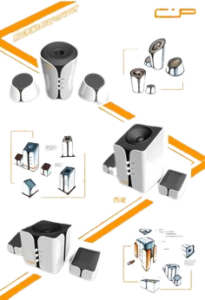

Are you ready to take your passion for design to new heights? Join us on

an exhilarating journey of innovation and creativity with our Professional

Diploma in Product Design and 3D Printing.

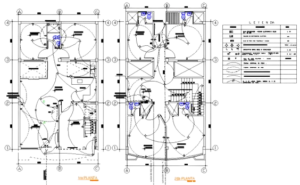

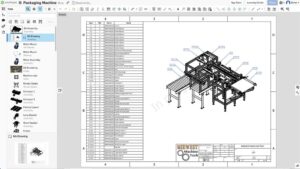

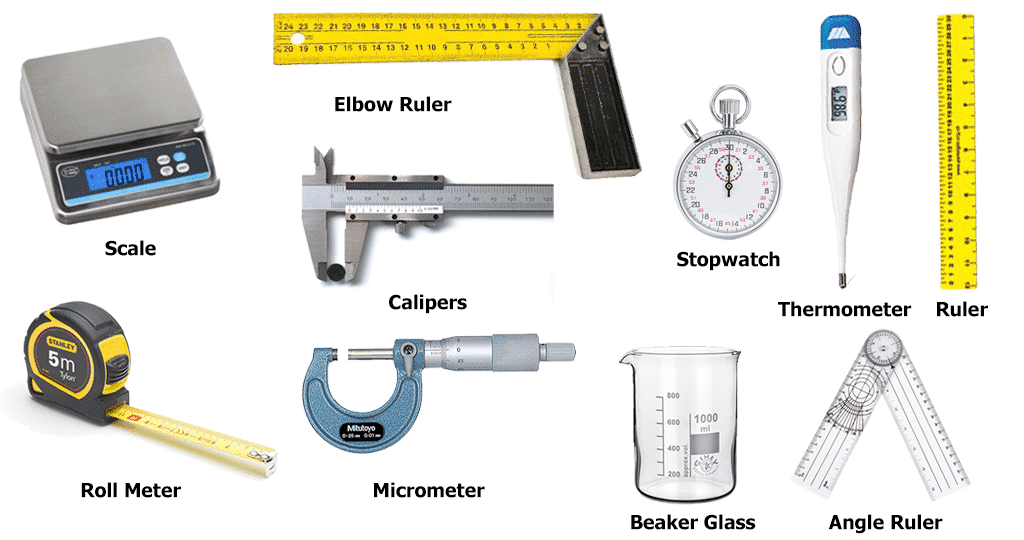

Designed for aspiring design professionals and working individuals seeking career advancement, this comprehensive program equips you with the skills, knowledge, and hands-on experience needed to excel in the dynamic world of product design.

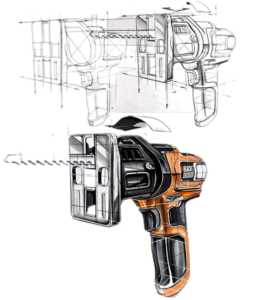

The Professional Diploma in Product Design and 3D Printing offers a comprehensive curriculum and hands-on experience, enabling

participants to become proficient in various aspects of product design. With industry-relevant knowledge, practical skills, and exposure to

real-world projects and industrial training, participants are well-prepared to excel in the field of product design and meet the demands of theindustry.

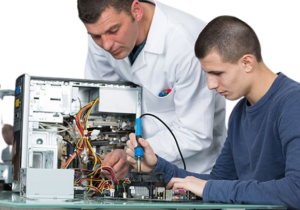

Offline Classes for combines

both theoretical and practical

aspects of learning

Course Duration: 6 Months

Weekend Classes Available

Suitable for: Working

Professionals

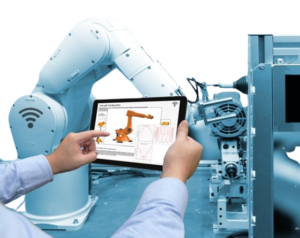

20 Days Industrial Training

for Practical Learning &

Industry Exposure

DesignXpert is a leading design education institute dedicated to nurturing and honing the skills of aspiring designers. Whether you are an aspiring product designer, a budding architect, or a passionate artist seeking to elevate your craft, DesignXpert has the perfect blend of expertise, resources, and industry exposure to fuel your creative ambitions.

Hello, Do You Have Any Query?