Exploring the World of Sheet Metal Design

Exploring the World of Sheet Metal Design:- In the fast-paced realm of product design, the art of Sheet Metal Design has emerged as a transformative force. With over 30-40 years of experience in the industry, I’m thrilled to delve into this innovative facet of product design, exploring techniques, tips, and answering your burning questions.

Understanding Sheet Metal Design

Sheet Metal Design is a specialized field within product design that focuses on creating functional and aesthetically pleasing metal components. These components are used in various industries, from automotive to aerospace. But what makes Sheet Metal Design truly fascinating is its ability to blend art with functionality.

The Form and Function

Sheet Metal Design allows for the creation of intricate and complex structures, all while ensuring they serve their intended purpose. It’s not just about bending metal; it’s an art that requires precision, creativity, and a deep understanding of materials.

Innovative Approaches in Sheet Metal Design

Innovation is the driving force behind any successful product design, and Sheet Metal Design is no exception. Let’s explore some groundbreaking techniques that have been shaping the industry.

1. Advanced CAD Software

Cutting-edge Computer-Aided Design (CAD) software has revolutionized Sheet Metal Design. It enables designers to create 3D models, simulate real-world conditions, and identify potential issues before production, saving time and resources.

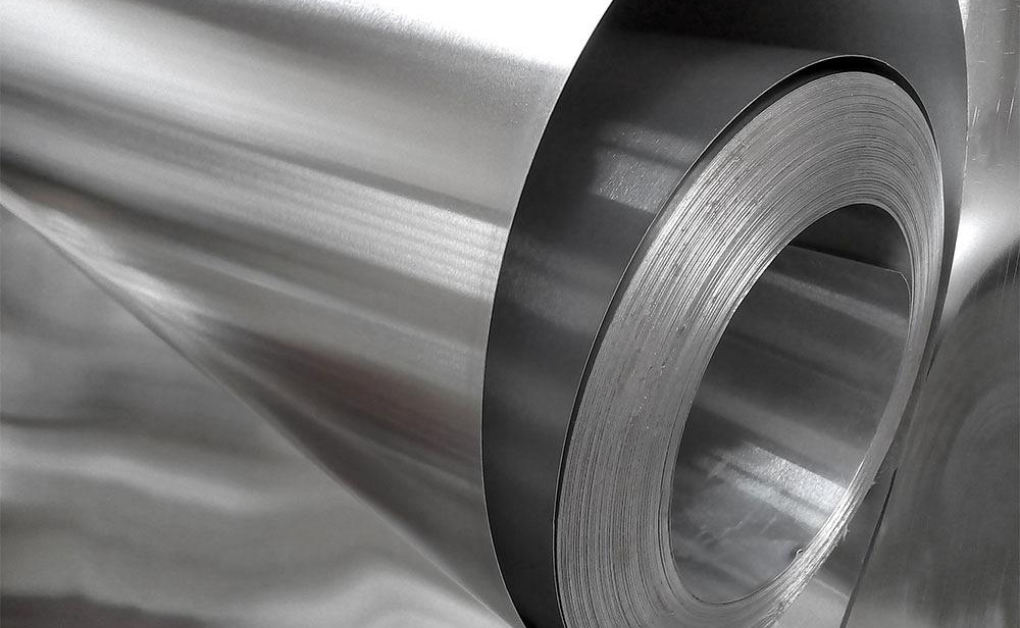

2. Material Selection

Choosing the right material is crucial in Sheet Metal Design. Innovations in material science have provided a broader spectrum of options, allowing for the creation of lightweight yet durable components. From aluminum alloys to high-strength steel, the possibilities are vast.

3. Rapid Prototyping

With the advent of 3D printing and rapid prototyping technologies, designers can quickly turn their ideas into physical prototypes, facilitating the testing and validation of their designs.

Tips and Tricks for Successful Sheet Metal Design

For those venturing into Sheet Metal Design, here are some invaluable tips to ensure your success in this intricate field:

1. Master the Basics

Before diving into innovative techniques, ensure you have a strong foundation in traditional Sheet Metal Design principles. Understanding how to create accurate flat patterns and bend allowances is essential.

2. Embrace Simulations

Leverage simulation tools to anticipate potential issues and make informed design decisions. This can save you from costly mistakes during the manufacturing phase.

3. Collaborate Effectively

Sheet Metal Design often involves collaboration with engineers and manufacturers. Effective communication and teamwork are keys to a successful project.

Q&A: Your Most Pressing Sheet Metal Design Questions

Let’s address some of the common questions that arise in the world of Sheet Metal Design:

Q: Which material is best for my project?

A: The choice of material depends on your project’s requirements. Aluminum is often used for its lightweight properties, while stainless steel offers corrosion resistance.

Q: How can I minimize production costs?

A: Optimize your design for manufacturability. Minimize complex bends and use standard tooling to reduce production costs.

Q: What software should I use for Sheet Metal Design?

A: Software like SolidWorks, AutoCAD, and Fusion 360 are popular choices for Sheet Metal Design.

In Conclusion

Exploring the World of Sheet Metal Design:- Sheet Metal Design is a captivating blend of art, innovation, and engineering. With the right knowledge, tools, and a dash of creativity, you can shape metal into remarkable creations that not only function flawlessly but also captivate the eye. As an industry expert with decades of experience, I hope this article has shed light on this fascinating field and provided you with valuable insights.

For more information :-A Comprehensive Guide for Sheet Metal Design