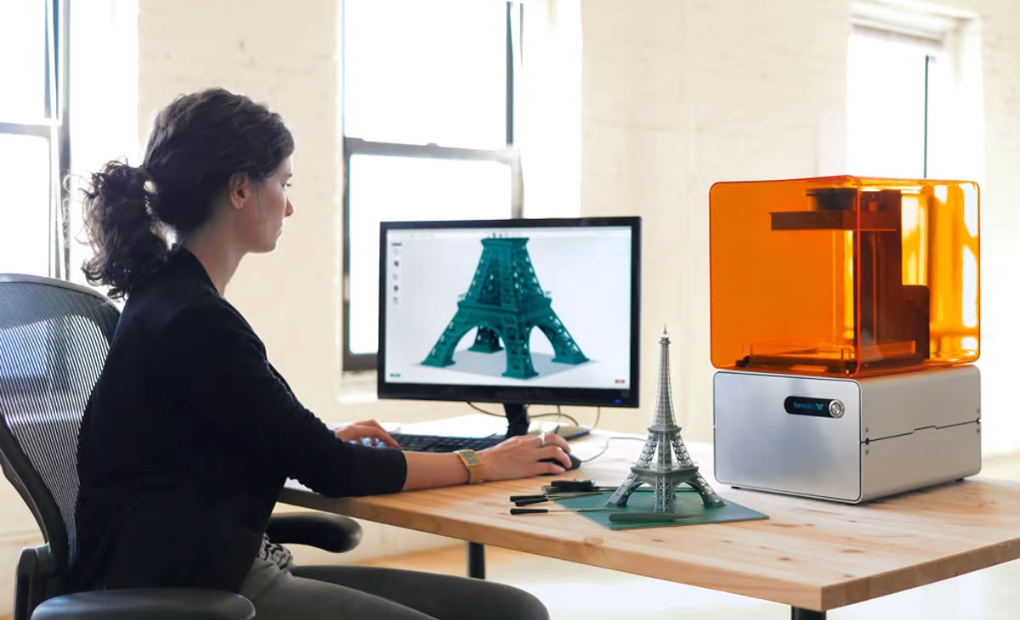

How 3D Printing is Revolutionizing Product Prototyping

The world of product prototyping has undergone a remarkable transformation in recent years, all thanks to the advent of 3D printing technology. Also known as additive manufacturing, 3D printing has emerged as a revolutionary tool that enables designers and engineers to create physical prototypes with unprecedented speed and precision. In this blog “How 3D Printing is Revolutionizing Product Prototyping”. we will explore the fascinating world of 3D printing and how it is revolutionizing product prototyping for both beginners and experienced professionals alike.

What is 3D Printing?

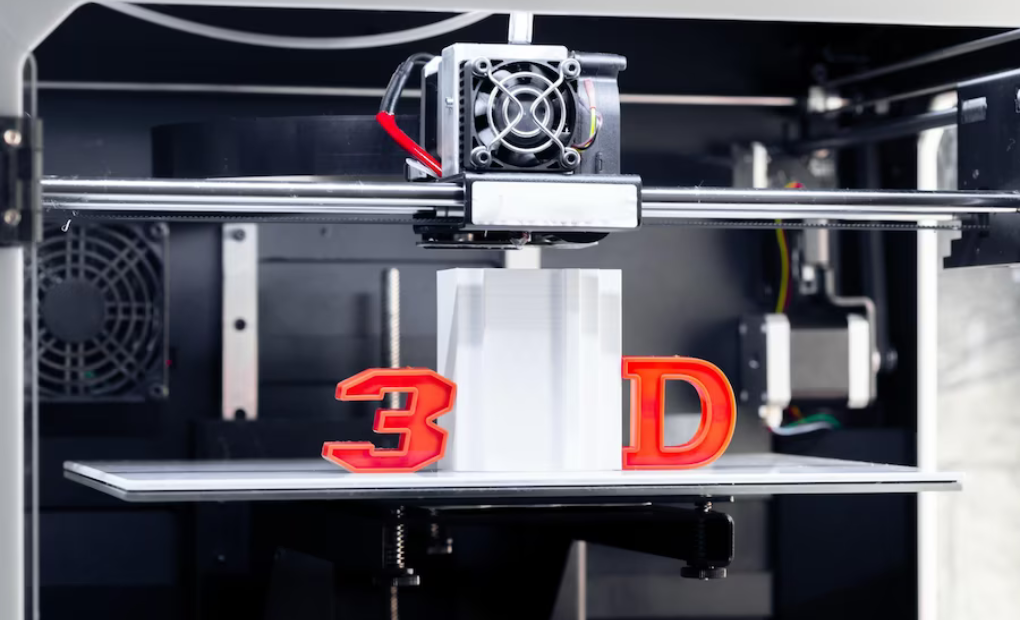

At its core, 3D printing is an additive manufacturing process where a three-dimensional object is created by depositing successive layers of material, one on top of the other. This process is fundamentally different from traditional subtractive manufacturing methods. Which involve cutting or carving a shape from a larger block of material.

At its core, 3D printing is an additive manufacturing process where a three-dimensional object is created by depositing successive layers of material, one on top of the other. This process is fundamentally different from traditional subtractive manufacturing methods. Which involve cutting or carving a shape from a larger block of material.

The Advantages of 3D Printing in Product Prototyping:-

Rapid Prototyping

3D printing has significantly accelerated the prototyping phase of product development. With traditional manufacturing methods, creating a prototype could take weeks or even months. In contrast, 3D printing allows designers to go from a digital model to a physical prototype in a matter of hours or days.

Cost-Effectiveness

3D printing eliminates the need for costly tooling and molds that are typically required in traditional manufacturing. This cost-saving benefit allows designers to iterate and test multiple design concepts without breaking the bank.

Design Flexibility

3D printing enables intricate and complex designs that would be difficult or impossible to achieve using traditional manufacturing techniques. Designers have the freedom to explore innovative shapes and geometries, pushing the boundaries of what is possible in product design.

Reduced Waste

Traditional manufacturing often results in significant material waste due to the subtractive process. In 3D printing, material is only used where it is needed, minimizing waste and promoting sustainability.

How 3D Printing Works:-

3D printing operates on the basis of a digital design file, typically in the form of a Computer-Aided Design (CAD) model. The process involves the following steps:-

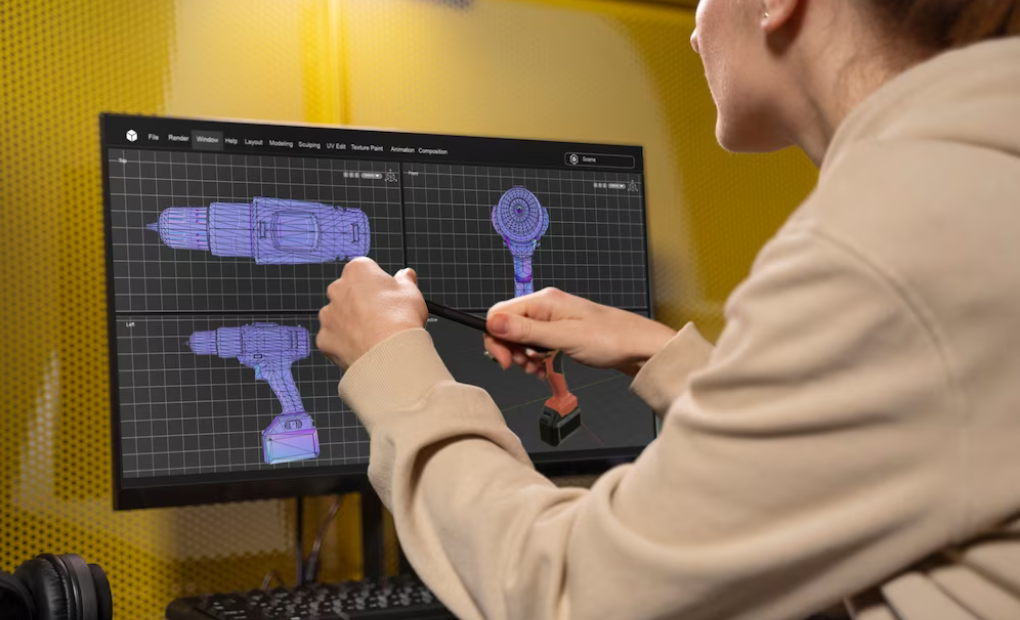

Design

The product idea is first translated into a 3D digital model using CAD software. Designers can manipulate and refine the design as needed before the printing process.

Slicing

The digital model is then sliced into thin horizontal layers using slicing software. This step prepares the design for the 3D printer to build each layer one by one.

Printing

The 3D printer follows the instructions from the slicing software to create the physical object layer by layer. Various 3D printing technologies exist, each with its unique strengths and materials. Such as Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS).

Post-Processing

After printing, the prototype may require post-processing, such as cleaning, curing, or finishing, depending on the 3D printing technology used and the desired end result.

Applications of 3D Printing in Product Prototyping:-

The versatility of 3D printing makes it applicable in various industries for rapid prototyping purposes:-

Automotive

3D printing enables automotive companies to create prototypes of car parts and accessories for testing and evaluation.

Aerospace

In the aerospace industry, 3D printing is used to create lightweight yet robust prototypes of complex components for aircraft and spacecraft.

Consumer Electronics

Prototyping electronic devices, casings, and connectors can be efficiently achieved through 3D printing.

Medical and Healthcare

3D printing is revolutionizing the medical field, allowing for the creation of patient-specific medical devices, surgical guides, and anatomical models for preoperative planning.

Architecture and Construction

Architects use 3D printing to build scale models of buildings and urban landscapes, aiding in visualizing designs and communicating ideas to clients.

Conclusion:-

3D printing has revolutionized the field of product prototyping, offering unparalleled speed, cost-effectiveness, and design flexibility. Whether you are a beginner or an experienced professional, embracing 3D printing as a prototyping tool opens the door to endless possibilities in product design and development. From concept to creation, 3D printing empowers designers and engineers to bring their innovative ideas to life with greater efficiency and precision than ever before. Embrace this transformative technology and embark on a journey of creativity and exploration in the world of product prototyping.