The Role of CAD Software in Modern Engineering

Computer-Aided Design (CAD) software has become an integral part of modern engineering practices, revolutionizing the way engineers design and develop products. CAD software offers powerful tools and capabilities that streamline the design process, enhance collaboration. In this blog, we will explore the critical role of CAD software in modern engineering and how it has transformed the landscape of product development and manufacturing.

What is CAD?

Computer-Aided Design (CAD) is a technology that utilizes specialized software to create, modify, and optimize designs for various engineering applications. CAD software allows engineers to create detailed 2D and 3D models of components, assemblies, and systems. These virtual representations serve as a digital blueprint, and documentation throughout the product development lifecycle.

1. Evolution of CAD Software

CAD software has come a long way since its inception in the 1960s. Initially, it was primarily used for 2D drafting and design. However, with technological advancements, CAD software has evolved to support 3D modeling, simulation, analysis, and visualization, making it an indispensable tool for engineers across various industries.

2. Enhanced Design Efficiency

One of the primary benefits of CAD software is its ability to significantly improve design efficiency. Traditional hand-drawn designs and blueprints were time-consuming and often led to errors. CAD software enables engineers to create accurate and complex designs quickly, reducing design cycles and speeding up product development.

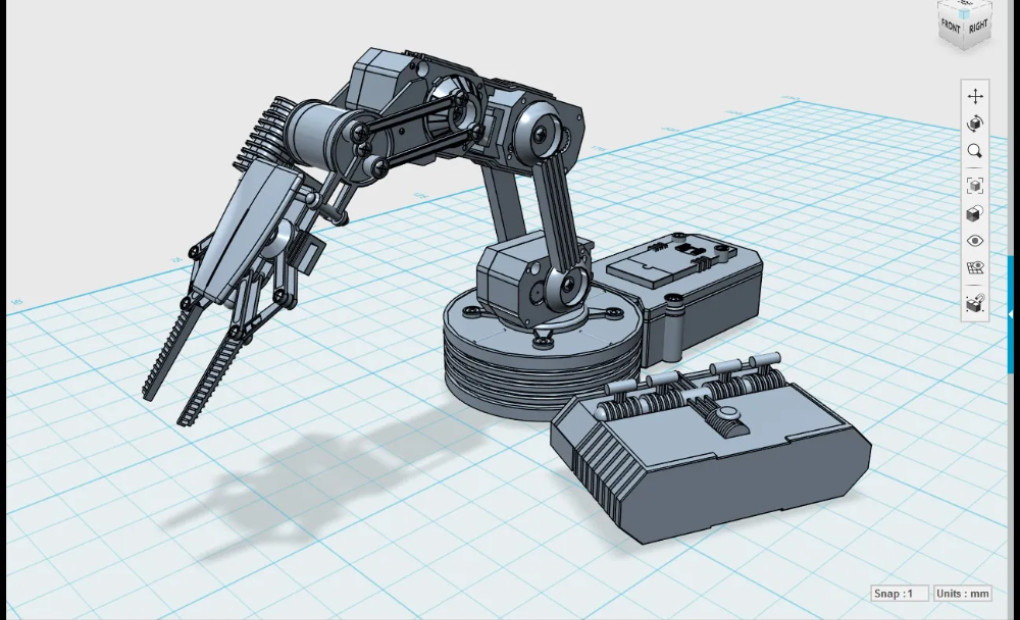

3. Precise 3D Modeling

CAD software offers powerful 3D modeling capabilities, allowing engineers to create detailed and realistic representations of their designs. 3D models enable better visualization, aiding in design evaluation and making it easier to communicate design concepts to stakeholders and clients.

4. Simulations and Analysis

CAD software provides simulation and analysis tools that help engineers test and validate their designs virtually. Finite Element Analysis (FEA) and Computational Fluid Dynamics (CFD) simulations allow engineers to assess the performance and behavior of products under different conditions, identifying potential issues before physical prototyping.

5. Iterative Design Process

CAD software enables an iterative design process, where engineers can quickly make changes and improvements to their designs based on feedback and insights. This flexibility ensures that the final product meets the desired specifications and performance requirements.

6. Collaboration and Communication

CAD software fosters collaboration among team members, allowing multiple engineers to work on the same design simultaneously. Real-time collaboration features enhance communication and ensure that everyone is on the same page during the design process.

7. Design Optimization

CAD software supports design optimization by enabling engineers to analyze different design iterations and select the most efficient and cost-effective solution. This optimization process results in better-performing products while minimizing material waste and production costs.

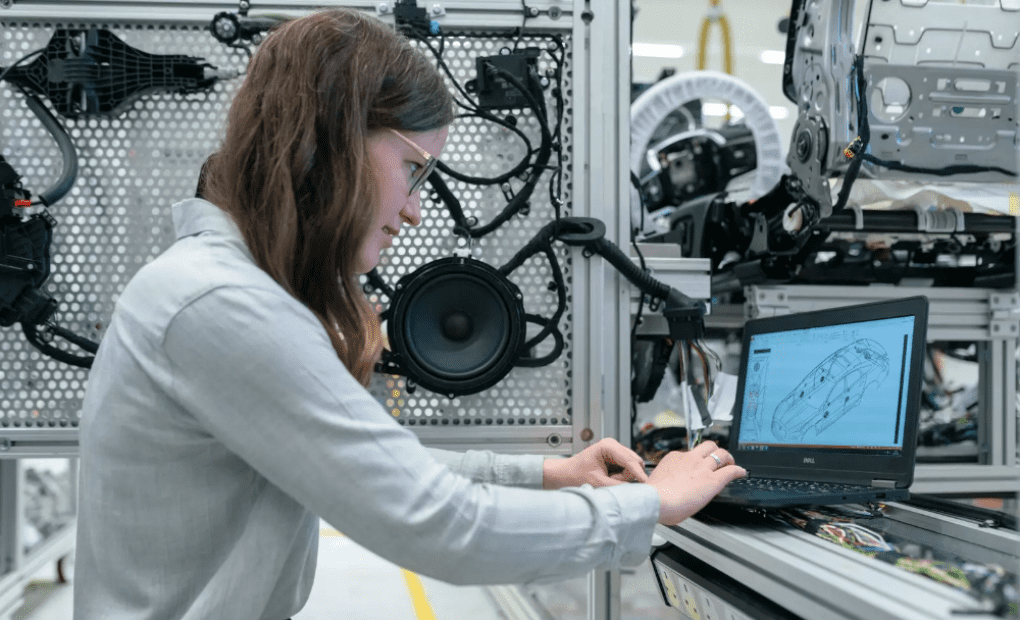

8. Integration with Manufacturing Processes

CAD software is seamlessly integrated with computer-aided manufacturing (CAM) and computer-aided engineering (CAE) tools. This integration enables engineers to transition from design to manufacturing seamlessly, reducing time-to-market and ensuring the manufacturability of the final product.

9. Documentation and Standardization

CAD software automates the creation of detailed technical drawings and documentation, adhering to industry standards and regulations. This standardization ensures that designs are compliant with relevant codes and standards, making the manufacturing and assembly processes smoother.

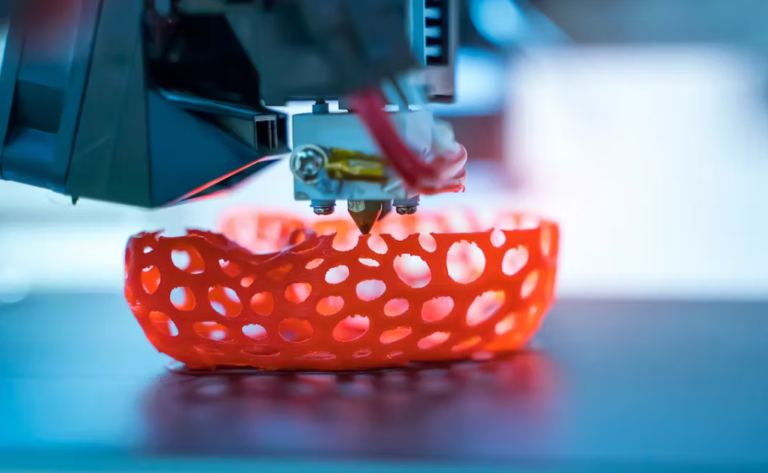

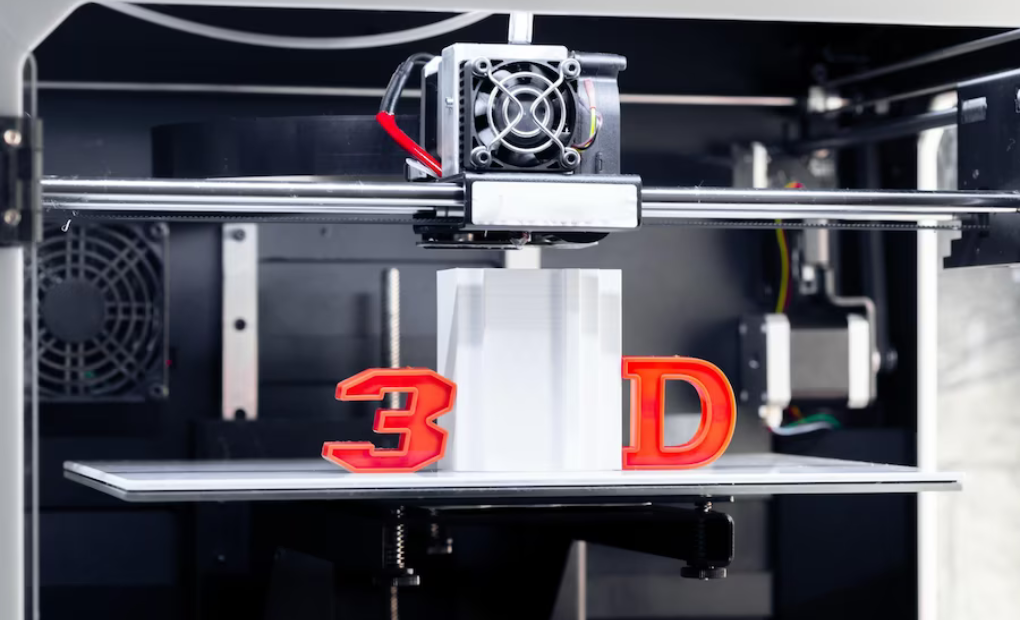

10. Digital Prototyping and 3D Printing

With CAD software, engineers can create digital prototypes that simulate the behavior and functionality of the actual product. Additionally, 3D printing has become increasingly accessible, allowing engineers to transform digital CAD models into physical prototypes for testing and validation.

Conclusion:-

CAD software has revolutionized modern engineering practices, offering a plethora of tools and features that enhance design efficiency, accuracy, and innovation. From 2D drafting to complex 3D modeling, simulations, and analysis, CAD software enables engineers to create and optimize designs that push the boundaries of what is possible. With seamless integration with manufacturing processes, CAD software ensures that designs are manufacturable and cost-effective.

The ability to visualize and iterate designs quickly, coupled with real-time collaboration, accelerates product development cycles. Additionally, the documentation and standardization capabilities of CAD software ensure that designs adhere to industry standards and regulations.

As technology continues to advance, CAD software will continue to play a central role in engineering, fostering a culture of innovation and driving the development of cutting-edge products that shape the future of various industries.