Unlocking the Power of Finite Element Analysis in Innovative Product Design

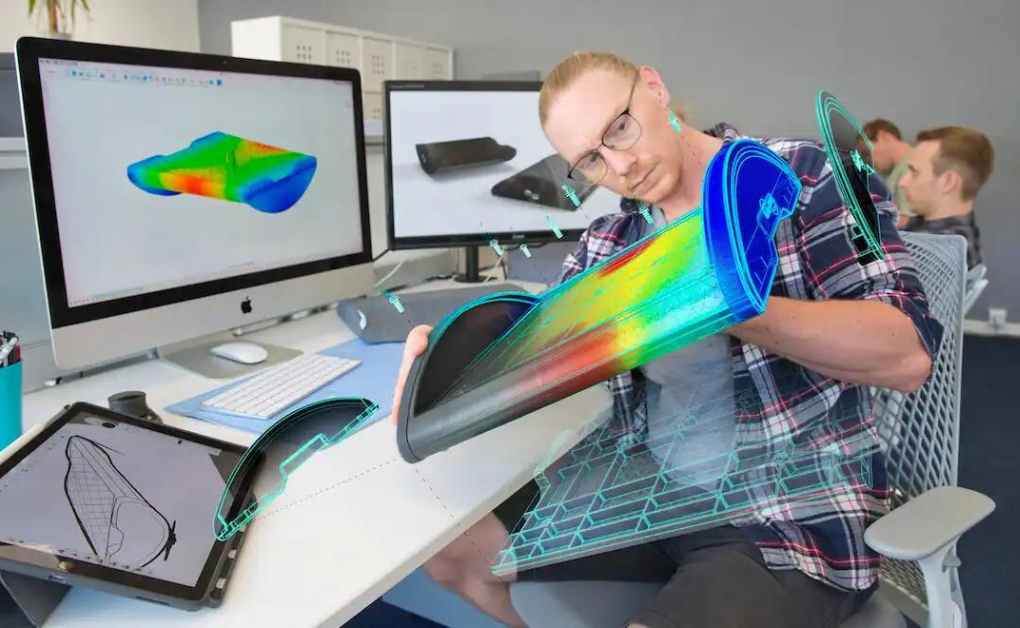

Unlocking the Power of Finite Element Analysis in Innovative Product Design:- In the dynamic international of product design, harnessing the strength of Finite Element Analysis (FEA) has turn out to be an essential tool for each seasoned specialists and rookies. With a legacy spanning many years, FEA has developed into a progressive method that guarantees the creation of progressive products that stand the test of time.

Why FEA is Used

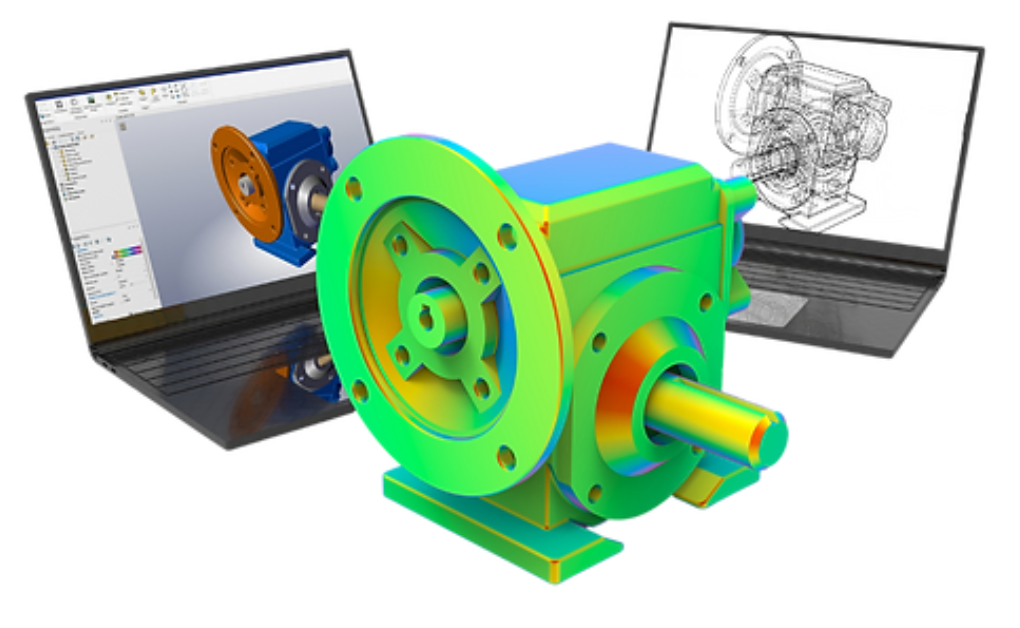

FEA is employed to scrutinize the structural integrity and performance of products during the design phase. It allows designers to simulate how a product will behave under various conditions and loads. This predictive analysis helps in identifying potential weaknesses and areas for improvement before any physical prototypes are created, ultimately saving time and resources.

Finite Element Analysis, or FEA, has earned its place as a cornerstone of modern engineering. It offers the capability to assess how a product will react to different forces and environmental conditions, providing invaluable insights for designers and engineers. By using FEA, a product’s performance, durability, and safety can be optimized before any physical prototypes are manufactured. This not only streamlines the product development process but also significantly reduces costs associated with design flaws detected after production has begun.

The Evolution of FEA

Finite Element Analysis wasn’t born overnight; it has a rich history dating back to the late 1950s. Engineers and mathematicians began developing FEA techniques to address the growing complexity of structures. Over the years, it has grown into a highly sophisticated field, with continuous advancements in software and computing power.

The Essence of FEA

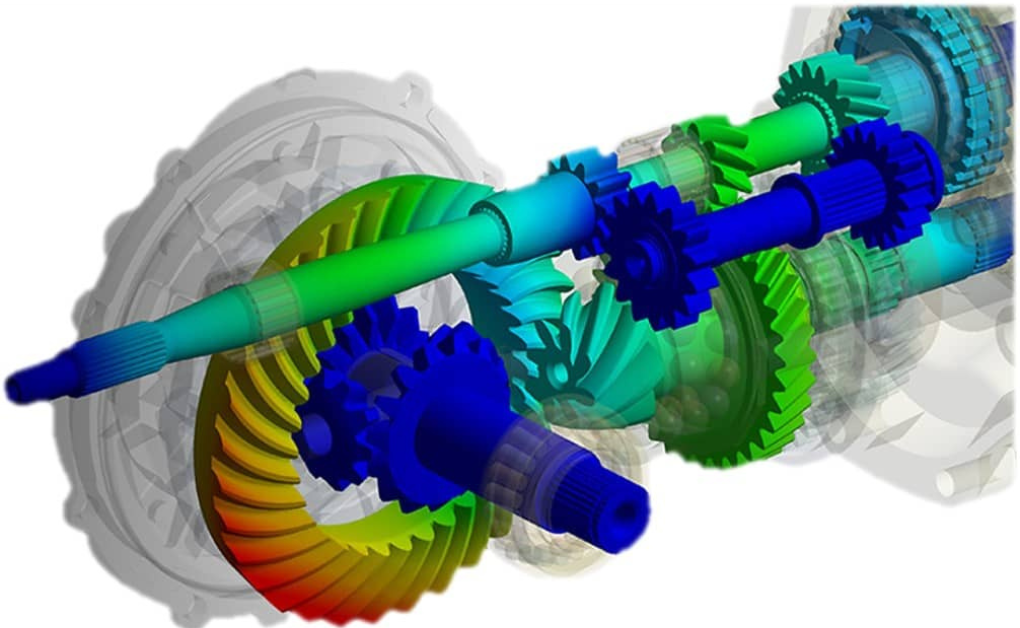

At its center, FEA divides complex structures into smaller, extra conceivable factors, inclusive of triangles or quadrilaterals. These factors are analyzed mathematically, allowing engineers to make correct predictions about how the whole shape will behave. In essence, FEA is sort of a virtual checking out ground in which products can be put thru their paces earlier than they’re bodily synthetic.

Types of FEA

There are various types of FEA, each tailored to specific applications. For example, structural analysis focuses on how forces and stresses affect a design, while thermal analysis helps in understanding temperature-related behavior. Fluid dynamics analysis, on the other hand, is used to study how fluids interact with the product.

Applications of FEA

FEA finds packages in an array of industries, starting from aerospace and car to scientific gadgets and client items. It has revolutionized the way engineers and architects method product development, allowing them to optimize designs and ensure product safety and longevity.

The applications of FEA are virtually limitless. In aerospace, it’s used to analyze the structural integrity of aircraft components, ensuring they can withstand extreme conditions. In automotive design, FEA is employed to enhance vehicle safety and fuel efficiency. Medical devices, such as implants and prosthetics, benefit from FEA to ensure they are both effective and durable. Even consumer goods like smartphones and kitchen appliances undergo FEA analysis to meet the rigorous demands of everyday use.

Making FEA Work for You

The beauty of FEA is its versatility and its ability to conform to diverse product design challenges. By the use of FEA, you can high-quality-tune your designs, reduce cloth waste, and in the long run create extra revolutionary, efficient merchandise.

To harness FEA effectively, consider these steps:

Collaborate with experts: Working with experienced FEA analysts can streamline the design process.

Continuous learning: Stay updated with the latest FEA software and techniques to remain at the forefront of innovation.

Validation and verification: Always validate your simulations with physical testing to ensure accuracy.

Iteration is key: Be ready to iterate your designs based on FEA results for continuous improvement.

FEA Tips and Tricks

Here are some invaluable tips to make the most of FEA in product design:

Collaborate with experts: Working with experienced FEA analysts can streamline the design process.

Continuous learning: Stay updated with the latest FEA software and techniques to remain at the forefront of innovation.

Validation and verification: Always validate your simulations with physical testing to ensure accuracy.

Iteration is key: Be ready to iterate your designs based on FEA results for continuous improvement.

Frequently Asked Questions

Q: Can FEA be used in the initial design phase?

A: Absolutely! FEA can be a vital tool during the early stages of design to assess the feasibility of your concept.

Q: Is FEA expensive to implement in product design?

A: While there are costs associated with FEA software and expertise, the long-term benefits often outweigh the initial investment.

Q: How accurate are FEA simulations?

A: FEA simulations can be highly accurate when applied correctly, but physical testing is often necessary for validation.

Unlocking the Power of Finite Element Analysis in Innovative Product Design:- In conclusion, Finite Element Analysis is a transformative force in the world of innovative product design. By leveraging the strength of FEA, you may make certain the structural integrity, overall performance, and sturdiness of your designs even as optimizing assets and reducing time-to-marketplace. Stay beforehand of the curve through embracing this contemporary generation, and allow your creativity and innovation flourish.